Material Structure: Bronze Wrapped Bearing with Oil Holes

Application Features: This is a thin wall wrapped bushing. It is suitable for a cost sensitive solution while the tolerance requirement is not critical. It has good corrosion resistance and heat conduction ability.

Typical Applications: Heavy Duty and Construction Machineries, Automotive Industry, Tractors, Trucks, Agricultural Machines and Mining Machines.

Material Structure: Special Treated Hardened Steel Bearings

Application Features: Designed for low speed and high load under lubricate, impact, powder and other harsh conditions, compared with the traditional steel bearing, the lubircating period is considerably extended and longer service time is guaranteed.

Typical Applications: Port Machinery, Forest Machinery, Construction Machinery, Truck Axles,Material Handling Machines and Hydraulic Cylinder Rod Eyes and Connecting Bearings

Material Structure: Steel+Sintered Bronze Lead Alloy

Application Features: These materials have low friction coefficient and good wear resistance and they are suitable for lubricated working conditions. To improve the lubricating performance, oil grooves or oil deposits could be optional designs.

Typical Applications: Connection Rods, Undercarriage Rollers, Hydraulic Cylinder Rod Eyes,Material Handling Machinery, Agriculture Machinery, Forest Machinery and so on.

Material Structure: Steel+Sintered Bronze Alloy Lead free.

Application Features: The lead free bronze lead alloys include two different materials. CSB-820 is an alloy with Nickle content and CSB-827 is an alloy with Bismuth content. These materials have low friction coefficient and good wear resistance,they are suitable for lubricated working conditions. To improve the lubricating performance, oil grooves or oil deposits could be optional designs.

Typical Applications: Connection Rods, Undercarriage Rollers, Hydraulic Cylinder Rod eyes, Material Handling Machinery,Agriculture Machinery, Forest Machinery and so on.

Material Structure: Steel Backed Fe-Ni Sintered Alloy with Solid Lubricants

Application Features: The alloy layer is designed with proper porous alignment to ensure the uniform dispersing of the solid lubricants providing good wear resistance feature.

Typical Applications: Guide Plates of Presser, Robots, Plastic Injection Machine Guide Plates, Tie-bar, Tyre Mold and other wear plates.

Material Structure: Steel Backed Bronze Powder with Solid Lubricants

Application Features: The uniform dispersed solid lubricants reduces the static and dynamic friction coefficient difference. This material can work stably even under the micro movement condition. Depending on request, oil indents or grooves could be designed on the bearing surface to hold oil or grease or any possible containments. It is suitable for the applications under middle to low load.

Typical Applications: Hydro-turbine, Plastic Injection Machine Guide Bushings, Tyre Mold and other wear plates and sliding bearings.

Material Structure: Steel+Sintered Tin Aluminum Alloy

Application Features: The material has good oil corrosion resistance feature. It is smooth and has outstanding imbedibility and anti-seizure performance. The working surface is not needed to be coated.

Typical Applications: Middle to Low Load Motors, Crankshaft of Air Compressors and so on.

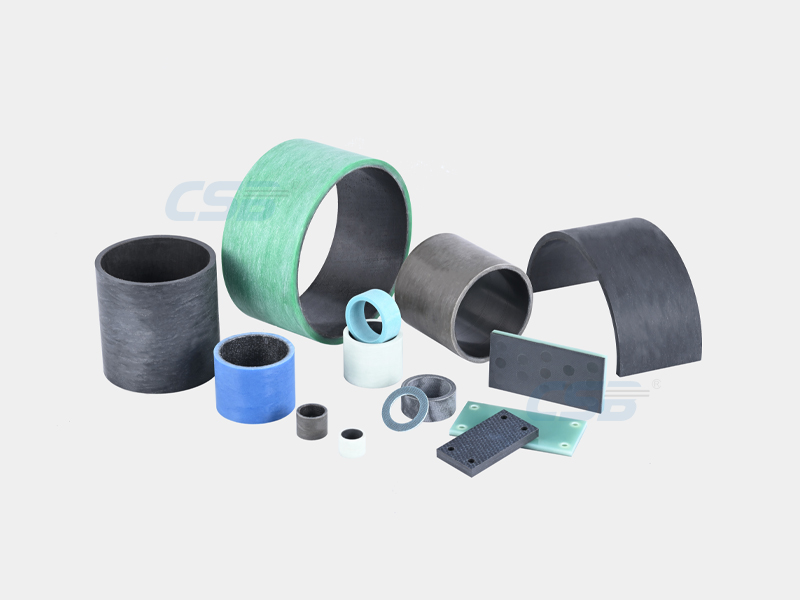

Material Structure: Wear Resistance Compound Plastic Products

Application Features: CSB-EPB Engineering plastic bearing material is based on high performance engineering plastic, by introducing the polymer technology to improve its characteristics, with special additives to achieve good wear resistance and self-lubricating features. These materials are widely used in automotive industry and high speed, underwater, high temperature and corrosion resistance application conditions. The applications for food industry conforms to FDA regulations are also available from CSB solutions.

Typical Applications: Automotive Industry, High-speed Applications, Underwater Applications, High Temperature and Corrosion Resistant Applications or the Food Industry requiring FDA compliance.

Material Structure: High Strength Glass Fiber+Epoxy Resin+Special Fiber +PTFE Fiber

Application Features: It has excellent wear resistance and low friction coefficient under high load and low speed working conditions. It has good self-lubricate characteristic and even under the long term of lacking oil lubricating condition, it still can work well with high load applied.

Typical Applications: Mateial Handling Machinery, Packing Machinery, Port Machinery and Servo Motors.

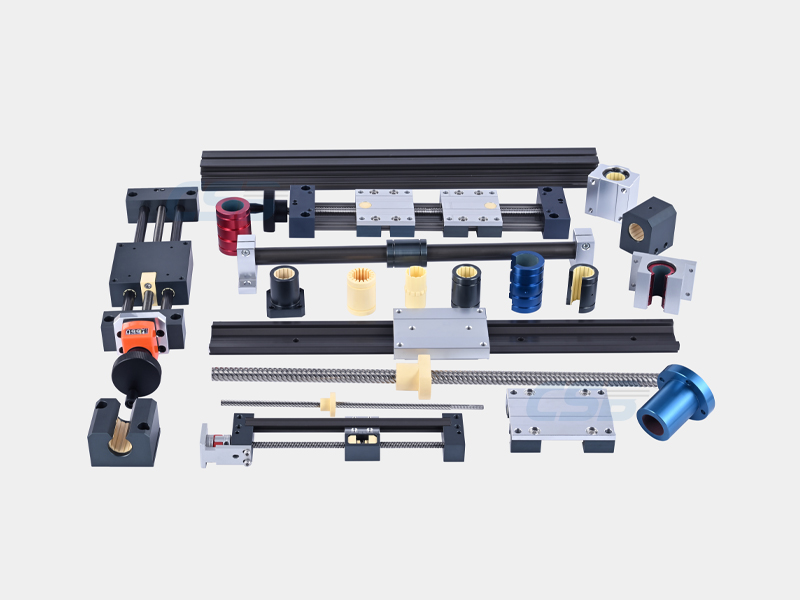

CSB-LIN® Linear guide rails & Screw nuts is designed with the maintenance free sliding components. All sliding parts are made of wear-resistant material CSB-EPB®. All shafts or guide rails are made of anodized aluminum alloy or stainless steel. Duo to the reasonable design of the material and components, CSB-LIN® Linear guide rails & Screw nuts is maintenance-free, resistant to dust, anti-corrosion and low noise.