Material Structure: Bronze Back+Porous Bronze Powder+PTFE/Fiber

Application Features: Excellent corrosion resistance and thermol conductivity. Easier press in installation feature.

Typical Applications: Automotive Door Hinges, Trunk Hinges, Hood Hinges, Screen Wipers, Handbrake Mechanism, Trailer Connectors, Outdoor Lift, Marine Winch, Marine Roller Chains, Dam Gate Transmission Mechanism, Drying Kiln, Textile Machinery, Metallurgical Machinery, Cylinder Trunnion Sleeves.

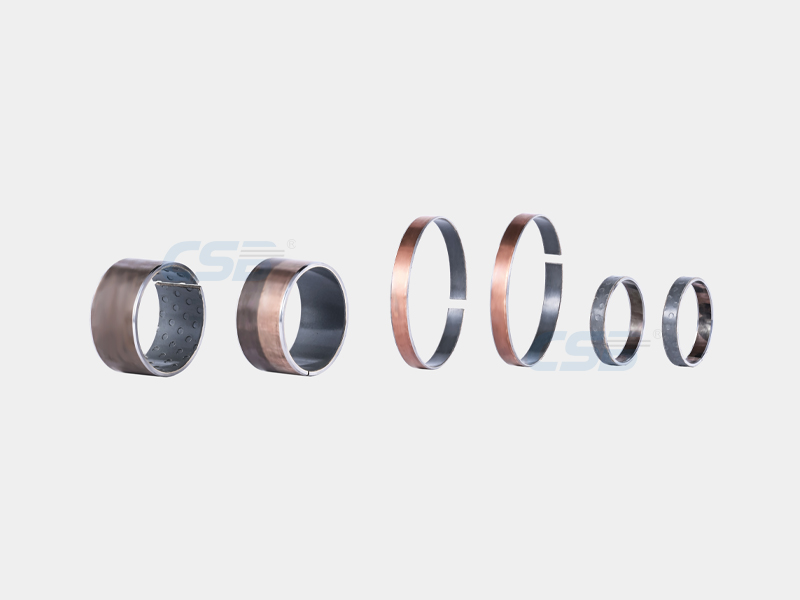

Material Structure: Metal Fabric+PTFE Fiber Compound Tape.

Application Features: The metal fabric backing provides wear resistance and self-lubricating properties with its light weight feature which is suitable for manual and automatic assembling.

Typical Applications: Automotive Door Hinges, Valve Mechanisms, OA Machinery and Textile Machinery.

Material Structure: Stretched Metal Mesh+PTFE/Fiber

Application Features: The stretched metal mesh is a light weight material with low linear expansion coefficients and good thermal conductivity. The PTFE filled in the mesh provides self-lubricating and noise absorbing features. The material could meet the interference fit requirement and could be calibrated after assembling.

Typical Applications: Automotive Door Hinges, Valve Mechanisms, OA Machinery and Textile Machinery.

Material Structure: Carbon Steel+Bronze Mesh+PTFE/Fiber.

Application Features: This material has good thermal conductivity and wear resistance. The steel backing improves the mechanical strength of the bearing as well as to allow thicker bearing wall designation requirement.

Typical Applications: Door Hinges, Valve Mechanisms, OA Machinery and Textile Machinery.

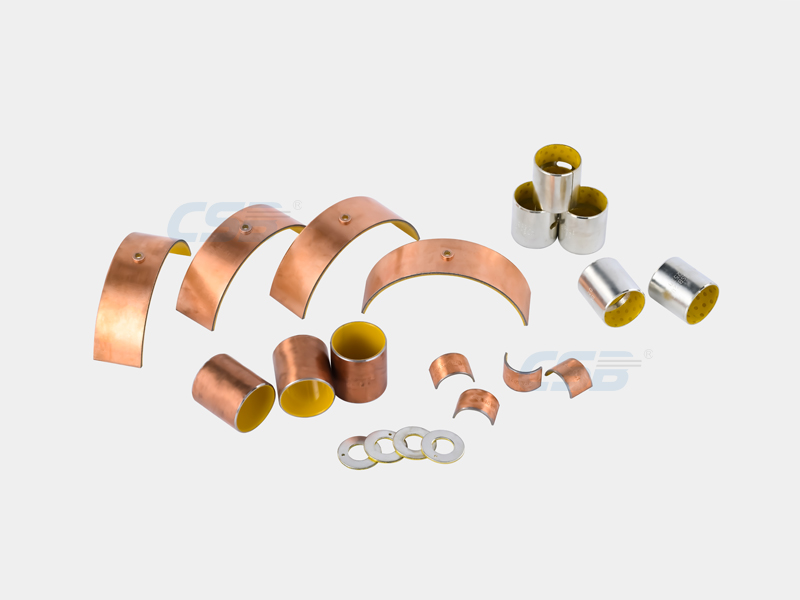

Material Structure: Carbon Steel+Porous Bronze Powder+Modified POM (oil impregnated)

Application Features: Excellent bearing capacity, low friction and good wear resistance, Suitable for rotation and vibration motion under heavy load and low speed, Oil impregnated polyformaldehyde bearing layer is good for the working conditions where insufficient lubricating is not available.

Typical Applications: Axiles of Truck and Commercial Vehicles, Brake Mechanisms, Suspension System and Agricultural Machinery, Forest Machinery, Material Handling Mchinery and other General Industry.

Material Structure: Carbon Steel+Porous Bronze Powder+Modified PVDF

Application Features: The standard material working layer is designed with oil indents,In order to improve the durability of the bearings, it is recommended to prelubricate before installing the bearing. It is suitable for boundary lubricate working condition or where continiously lubricating is not accessible.

Typical Applications: Automotive Air Conditioner Compressor, Suspension System, Seat Recliner, Hydraulic Components like Piston Pumps and Motors, Rotary Motors,Agricultural Machinery, Forest Machinery, Material Handling Mchinery and other General Industry.

Material Structure: Carbon Steel+Porous Bronze Powder+PA Resin

Application Features: Designed for working conditions of high load, high wear resistance, less maintenance or maintenance-free.

Typical Applications: Axle Steering Gear.

Material Structure: Carbon Steel+Porous Bronze Powder+Modified PI

Application Features: Machinable after installation. Designed for the working condition under high speed operation with boundary lubrication.

Typical Applications: Automotive and Commercial Air Conditioner Compressor, Gear Boxes amd Piston Pumps.

Material Structure: Carbon Steel+Porous Bronze Powder+Modified PEEK

Application Features: Designed for medium and high load working conditions with boundary lubrication.

Typical Applications: Hydraulic Motors,Axial and Radial Pumps, Diesel Engine Common Rail Systems, Heavy Truck Brakes.